Accelerating Sustainable Connections

We are passionate about regional connectivity and work to provide the best possible products, services and support to our customers. Since 1981 we have built and delivered aircraft to over 200 airlines, in 100 countries across the world, and supported these same airlines in providing essential links for passengers and communities.

We supply essential regional connectivity for people, businesses and communities all over the world. Whether it is linking local business to capital cities, taking travellers deep into the heart of the world’s natural beauty or delivering vital medical aid and supplies to communities that cannot otherwise be accessed, our aircraft help bring people, ideas, goods and markets together.

ATR is all about connections. We are driven by our vision to accelerate sustainable connections worldwide, focusing on innovation, safety and sustainability as the driving forces of everything we do.

This is how, year after year, we continue to deliver a family of highly efficient, versatile, and innovative turboprop aircraft that make a significant difference across the globe, fostering growth and enhancing regional connectivity.

ATR is a joint partnership between two major European aeronautics players, Airbus and Leonardo

Airbus

Read more

Airbus

Airbus is a global leader in aeronautics, space and related services. In 2019, it generated revenues of 70 billion euros and employed a workforce of around 135,000. Airbus offers the most comprehensive range of passenger airliners. Airbus is also a European leader providing tanker, combat, transport and mission aircraft, as well as one of the world’s leading space companies. In helicopters, Airbus provides the most efficient civil and military rotorcraft solutions worldwide.

Leonardo

Read more

Leonardo

Leonardo is one of the world’s top aerospace, defence, security and cyber companies, with over 46,000 people on 120 sites worldwide and a turnover in excess of 12 billion euros. Leonardo creates today the technology that will make tomorrow safer, offering products and services that range from helicopters to aircraft, electronics, cyber protection, security and beyond.

What we do

Our family is comprised of four variants of two aircraft:

How we do it

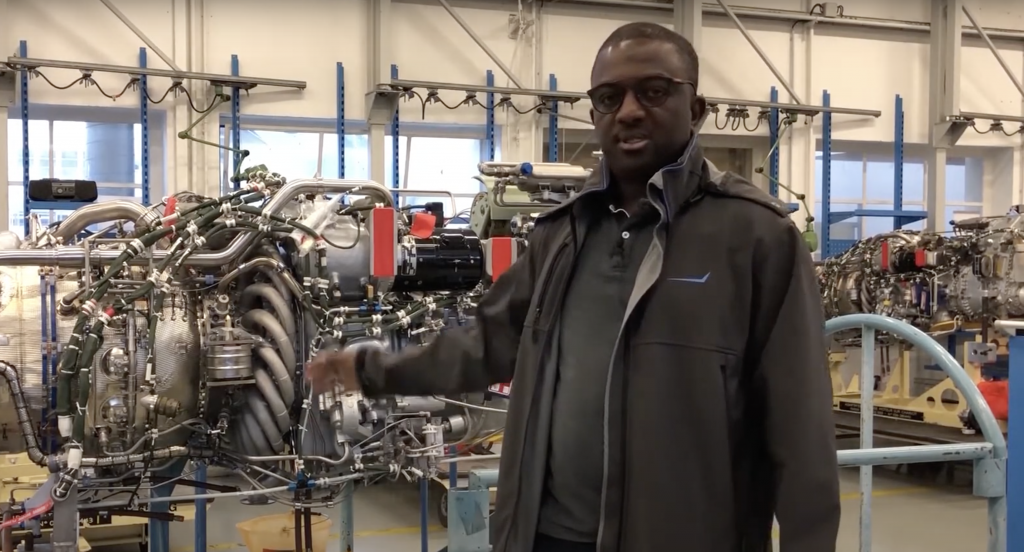

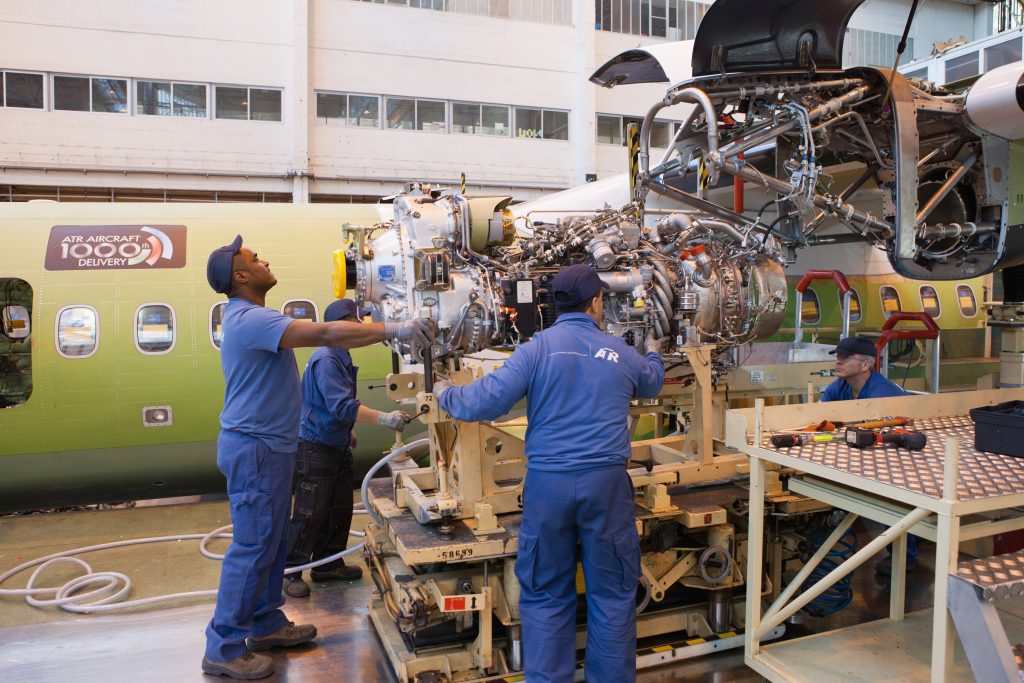

We offer airlines the most efficient, versatile, innovative, and responsible regional aircraft on the market. Our aircraft have been designed and built around turboprop engines. The efficiency of our aircraft means they:

- burn 45 % less fuel than a similarly sized regional jet

- emit 45% less CO2 than a similarly sized regional jet

- access challenging terrains, hence widening route opportunities

- offer low operating costs, ensuring the viability of the shortest, thinnest routes.

With our focus on continuous innovation, we are constantly bringing evolutions and new technologies to our aircraft to perfectly meet the needs of our market. Passengers will arrive at their destination in one of our stylish, modern, and comfortable cabins.

A worldwide presence

Flexibility and accessibility are key values of ATR’s philosophy. Thanks to a global network of customer services centres, warehouses, commercial offices and training centres, ATR aims to be close to its operators and responsive to their needs. ATR is steadily expanding its global presence, accessing new markets and engaging in new partnerships and business opportunities, to the benefit of the whole ATR community. ATR continues to enhance the competitiveness and value of its products, by leveraging technology, improving efficiency and influencing the global business environment by addressing political and regulatory issues. ATR uses the knowledge and experience of in-country experts to develop local partnerships and be even closer to the specific needs of its operators. A key to business success.

Commercial Offices

Customer Service Centres

Spare Parts Warehouses

Regional Customer Support Offices

Training Centres

ATR Representation Office

12 Seletar Aerospace Link #02-00 Singapore 797553

ATR Representation Office

12 Seletar Aerospace Link #02-00 Singapore 797553

ATR Customer Service

1 Allée Pierre Nadot 31712 Blagnac

ATR Customer Service

1 Allée Pierre Nadot 31712 Blagnac

ATR Eastern Support Pte Ltd (AES)

12 Seletar Aerospace Link #02-00 Singapore 797553

ATR Eastern Support Pte Ltd (AES)

12 Seletar Aerospace Link #02-00 Singapore 797553

ATR Eastern Support Pte Ltd c/o DHL Supply Chain Pte Ltd – ARC

Tampines LogisPark 1 Greenwich Drive ARC Warehouse Block 1, Level 2 Singapore 533865

ATR Eastern Support Pte Ltd c/o DHL Supply Chain Pte Ltd – ARC

Tampines LogisPark 1 Greenwich Drive ARC Warehouse Block 1, Level 2 Singapore 533865

ATR C/O Airbus Brasil Negócios Aeroespaciais Ltda

Avenida Olavo Fontoura, 1078 Aeroporto Campo de Marte – Setor C, Lote 3 02012-021 Santana – São Paulo, SP Brasil

ATR C/O Airbus Brasil Negócios Aeroespaciais Ltda

Avenida Olavo Fontoura, 1078 Aeroporto Campo de Marte – Setor C, Lote 3 02012-021 Santana – São Paulo, SP Brasil

ATR South African Training Center (Proprietary) Limited

Hangar 7 Denel Industrial Properties Denel North Road Kempton Park Johannesburg – South Africa

ATR South African Training Center (Proprietary) Limited

Hangar 7 Denel Industrial Properties Denel North Road Kempton Park Johannesburg – South Africa

ATR C/O Virgin Australia Hangar

83 – 87 Pandanus Ave, Brisbane Airport Park Qld 4007 Australie

ATR C/O Virgin Australia Hangar

83 – 87 Pandanus Ave, Brisbane Airport Park Qld 4007 Australie

Training centre Miami

4355 NW 36th St Miami Springs FL 33166 U.S.A.

Training centre Miami

4355 NW 36th St Miami Springs FL 33166 U.S.A.

Training centre Toulouse

1 Allée Pierre Nadot 31712 Blagnac France

Training centre Toulouse

1 Allée Pierre Nadot 31712 Blagnac France

Over 4 decades of excellence

1981

2022